By David Newcomb, Contributing Author

Road professionals will have the opportunity to innovate asphalt pavement design and asphalt quality like never before through the implementation of proven technology developed over the past two decades, and the country will need the benefits of these recent developments to help mitigate construction-caused traffic congestion of the future.

First, perpetual pavement lets engineers develop cross-sections where distresses occur only in the shallow sacrificial surface layers. This is accomplished through placing layers thick enough to lower the strains at the bottom of the asphalt so that cracking will not readily initiate and propagate. As surface distresses occur, rapid rehabilitation techniques that minimize traffic delays, like milling and filling, will provide the tools for contractors to get in and out of the work zone.

Second, recent research shows that it is practical to use asphalt mixture performance testing in the design and construction of asphalt layers. Using a balanced mix design (BMD) approach to minimize cracking and rutting helps to ensure that the most durable and economical combination of materials are employed to achieve the longest possible performance and to lengthen intervals between minor rehabilitation. This helps to minimize traffic delays during construction and resurfacing.

In the BMD approach (Figure 1), a cracking test establishes the lowest asphalt content that provides the needed cracking resistance. A rutting test identifies the highest asphalt content that delivers the needed rutting resistance while avoiding permanent deformation. These boundaries for cracking and rutting give a range over which the asphalt content may be selected for production.

The combination of perpetual pavement design and the use of BMD will optimize the structural design and performance of the asphalt mixtures. The need for rapid, long-life, high quality asphalt pavement construction is clearly shown in maps produced by the FHWA in Figure 2. The map on the left side of the picture (Figure 2(a)) illustrates the congested areas in the U.S. as of 2011 and the map on right side (Figure 2(b)) shows the expected level of congestion in the year 2040. Departments of transportation and contractors must expect a great deal of pressure for the construction of long-lasting roads with minimal intervention.

Perpetual Pavements

The notion that thick, well-built asphalt pavements could last many years with simple resurfacing has been acknowledged by engineers for a long time, but there were relatively few studies of long-term pavement performance.

In fact, most civil engineering students have been taught that they should design the thickness of asphalt pavements for 20 years of traffic. This led to the idea, in some people’s minds, that asphalt pavements lasted only 20 years when, in fact, many of these pavements were still in moderate to good condition at the end of two decades.

However, studies of long-term performance, such as Mahoney’s (TRB, 2001), showed that most thick asphalt interstate pavements in Washington had a median age of between 30 and 50 years with most of those being between 40 and 50 years; far better than 20 years.

In the 1970s, researchers at Berkeley researched the fatigue of asphalt mixes and noticed that there seemed to be a level of bending strain low enough that it would not initiate cracking (Monismith & McLean, AAPT, 1972).

Known as the fatigue endurance limit (FEL), it has been used in the study of other types of materials such as steel for many years. The FEL was important to perpetual pavements because it defined the design strain for the heaviest traffic loads. Lighter loads would produce strains lower than the FEL, so they do not contribute to bottom-up fatigue cracking.

Mike Nunn (TRL, 1997) at the Transportation Research Laboratory in the U.K. was among the first to validate the relationship between the total asphalt thickness and long-lasting pavements. Researchers at the University of Illinois were among the first in the U.S. to develop a perpetual pavement design procedure (Thompson & Carpenter, 2004).

Since then, several national and international Departments of Transportation have either developed or adopted other versions of perpetual pavement design, such as the one developed by Dr. Timm at Auburn University (IJPE, 2006) for the Asphalt Pavement Alliance.

The features that need to go into a perpetual pavement (Figure 3) include a solid foundation, a thick asphalt section to prevent the initiation of deep cracking and rutting, and a design for the heaviest wheel loads expected in the future traffic mix.

The foundation must be made of soil and base materials that resist seasonal changes such as excessive weakening, frost heave, or volume change, as well as support the weight of construction traffic and provide long-term resistance to degradation.

The upper layers of the pavement must be comprised of well-constructed, high-performing asphalt mixtures. This typically includes two to three different types of mixtures with a coarser, more economical rut-resistant material as the bottom lift and a finer, higher cost (e.g., polymer modified) mixture at the surface that should be resistant to both cracking and rutting.

However, to get the best performance out of asphalt mixtures, new approaches related more directly to performance must be adopted.

Performance Testing

The testing of asphalt mixtures for certain performance parameters has been done for a long time.

While these tests were useful, they could only be applied during mixture design, as most were too cumbersome or slow to be useful in the field. For the most part, there was a reliance on volumetric properties in the laboratory and field, such as air void content, asphalt content, density, and voids in mineral aggregate.

The time-tested empirical relationships between volumetric properties and the suitability of asphalt mixtures generally held well if they were used for mixtures of the time with low to moderate RAP content, non-synthetic aggregates, and asphalt binders, which had none or moderate levels of polymer.

In today’s climate, there is a need for a more discerning approach using actual cracking and rutting parameters for mixtures containing materials such as warm mix additives, high RAP contents, recycling agents, high polymer content binders, plastic aggregates and other materials being introduced into the mixtures.

Dr. Zhou of TTI first introduced the concept of Balanced Mix Design in 2007 (AAPT) in which the asphalt mixture satisfies the required cracking and rutting resistance.

Dr. Epps Martin of TTI is currently conducting a performance study using test sites throughout Texas. There are many variations of rutting and cracking tests that have been used to ascertain the mechanical behavior of hot mix asphalt.

Rutting tests have been in wide use since the 2000s and have included the Hamburg Wheel Test (HWT), the Asphalt Pavement Analyzer (APA), and the IDEAL Rutting Test (RT). The HWT uses a loaded steel wheel, and the APA uses wheel-loaded pneumatic tubes as means of applying loads. The RT uses a testing jig that applies a continuously increasing shear load to the sample.

Laboratory cracking tests for asphalt mixtures include the Illinois Fracture Index Test (IFIT), the Disk-Shaped Compact Energy Test (DCT), the Semi-Circular Beam (SCB) Test, Indirect Tensile Cracking Test (CT), Bending Beam Fatigue (BBF), and University of Florida Indirect Tension Test Method (UF-IDT). In addition to the rutting and cracking tests, standards are being developed for aging mixtures so that they more closely mimic the aging conditions in the field at appropriate times.

The goals for performance testing are to standardize test procedures that can directly and easily measure for rutting and cracking resistance in the field and be widely applicable to a variety of asphalt mixtures.

By incorporating rutting and cracking resistance in the BMD mix design approach, engineers and contractors will have a more realistic view of pavement performance during construction. It is envisioned that the BMD method will result in improved asphalt mixtures that will last longer between resurfacings, improving the life cycle cost of asphalt mixtures.

Impact

Perpetual pavements and performance testing will not solve all the future traffic congestion problems in the U.S., but they can provide ways to lessen the impact of construction and rehabilitation activities on the growing traffic problems.

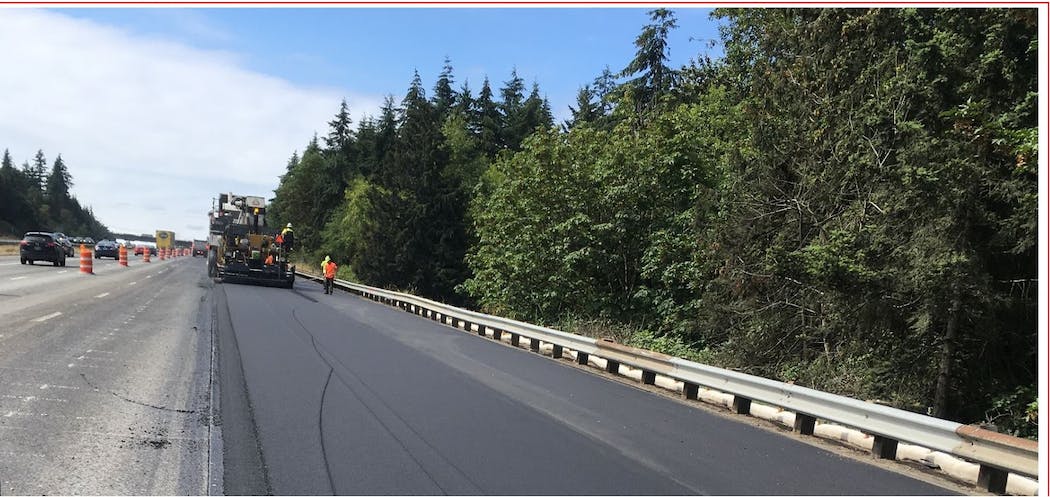

Rapid construction and rehabilitation, such as shown by the mill and overlay project in Figure 4, will require the use of perpetual pavements so that future repairs will be confined to shallow areas in the pavement structure.

Performance testing and BDM will improve asphalt mix design and quality control lengthening the time between required rehabilitation activities. Greater innovation through BMD will be possible as our test methods focus on results instead of recipes to allow the use of a wider variety of paving materials. R&B

David Newcomb is the division head of materials and pavements at the Texas A&M Transportation Institute.