By Shane Szalankiewicz and Nick Burdette, Contributing Authors

Performing maintenance on high-traffic bridges with difficult access or limited options for closures highlights the importance of ensuring materials last as long as possible.

Enter polyester polymer concrete.

Known as PPC, this material uses polyester resins as the binder instead of traditional Portland cement. Given its resilience and durability, it provides transportation agencies a key strategy for extending a bridge deck’s life and protecting its surface for the long-term.

Since 2016, the Pennsylvania Department of Transportation (PennDOT) has used PPC for many bridge decks, particularly those with high average daily traffic counts and access difficulties.

Adding a PPC overlay can protect a deck for decades, even in harsh environments, reducing needed maintenance substantially. Pennsylvania — which has more than 25,000 state-owned highway bridges — has already added the overlay on hundreds of bridges. And PPC has been incorporated into PennDOT’s standard specifications, to be considered as a protective overlay on bridge replacement, rehabilitation and preservation projects.

PPC on the Jerome Street Bridge

The Jerome Street Bridge is a rare steel crescent arch bridge located in McKeesport, Pa. Built in 1937, it has been designated a “Historic Landmark” by the Pittsburgh History and Landmarks Foundation.

It serves as a gateway to McKeesport, as well as the primary access route from points north and west to hospitals, businesses, and schools within the downtown area. This bridge supports four lanes of traffic and carries 18,000 vehicles daily.

The Jerome Street Bridge had significant corrosion and deterioration, and it needed a new deck, concrete substructure repairs, and bearing replacements.

The rehabilitation was completed in November 2022. As part of the deck replacement, the surface was overlaid with one of the largest applications of PPC on a major river span in Pennsylvania.

After the new 9-inch lightweight concrete deck was reopened to traffic in December 2021, a non-structural 3/4-inch PPC overlay was added in two stages in the next construction season, beginning in May 2022.

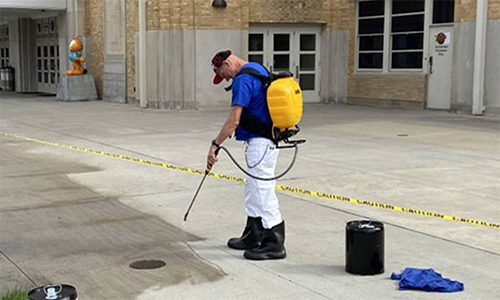

This process began with required 1/4-inch scarification with a micromill, and then shot blasted to clean the road surface of any loose aggregate or contaminants. A high molecular weight methacrylate as primer was then applied to the clean and dry surface.

This primer promotes adhesion of the overlay to existing concrete. The PPC is placed on top of the primer after at least 15 minutes and within two hours. A sand top dressing is then applied while the PPC is still wet.

The expectation is that the overlay will protect the historic bridge’s deck into the 2050s.

Why PPC?

PPC is a desirable choice for bridges such as Jerome Street, where durability and long life are key considerations. The option provides some major benefits for bridge deck projects, including:

It has good corrosion resistance: Polyester polymer concrete is resistant to chemicals, UV light and extreme temperatures, making it suitable for use in harsh environments.

PPC has a higher tensile strength than traditional concrete, which makes it less prone to cracking.

PPC is lighter than standard concrete (about 135 pcf versus 150 pcf). This can make it a good choice for bridges where weight is a critical consideration.

PPC requires less curing time than traditional concrete (approximately 4 hours), a plus when resuming traffic quickly is important.

PPC has extremely low or negligible permeability for chloride ions, making it a good choice for regions where deicing chemicals are regularly used on roads and bridges.

Because of the high-strength chemical bond of the PPC to the substrate, there is no need for additional hydrodemolition to further roughen the surface before application as is necessary with other overlay options.

Although the overlay was not considered structural for the Jerome Street Bridge project, PPC can be considered structural on preservation projects due to the bond strength being greater than 200 psi. This means an existing deck can be scarified to remove the desired overlay thickness, shot blasted, then the overlay is placed, eliminating the need to raise expansion dams and adjust approach roadway.

While these benefits are compelling, PPC is more expensive than traditional concrete and some other overlay options. Nevertheless, for many high traffic bridges, the initial higher cost will be offset over the life of the bridge by the durability and strength of the overlay that allows maintenance to be deferred for a longer period.

PennDOT uses a variety of overlay strategies on their bridge decks. PennDOT typically uses PPC on bridges with a better deck condition, where a thin overlay is appropriate. PennDOT’s rule of thumb is if hydrodemolition is needed to remove delaminations, and then use a more economical overlay for the thicker application required.

Smart Asset Management Strategy

Asset management involves finding the lowest life cycle cost for bridges, and PPC is one important tool to protect bridge decks. Used on new bridge decks (on high average daily traffic roads and where access is difficult), rehabilitation, and preservation projects, the product has a service life of approximately 30 years.

In many cases, the goal after 30 years would be to remove the overlay through milling/scarification and placing another overlay to last for decades longer, preventing a premature deck replacement. This approach to bridge maintenance is especially useful for bridges that would be very disruptive to close for long-term repairs.

Given the hassle for travelers and the long-term closures often necessary for a full bridge deck replacement, transportation agencies understandably seek to preserve existing decks as long as possible.

PPC overlays are a good help in that endeavor, particularly in northern states such as Pennsylvania, where de-icing solutions are regularly used and keeping chlorides and water out of roads is critical to their longevity.

In a state with tens of thousands of bridges, the strategy is an important part of a larger asset management plan. Its application on existing bridge decks and on new decks, such as the Jerome Street bridge, will keep bridges well protected for decades to come. R&B

Nick Burdette, P.E., is a senior bridge engineer for HDR and led design work on the Jerome Street bridge. Shane Szalankiewicz, P.E., is the district bridge engineer for PennDOT’s District 11, which covers the Pittsburgh area.